Setting a new standard

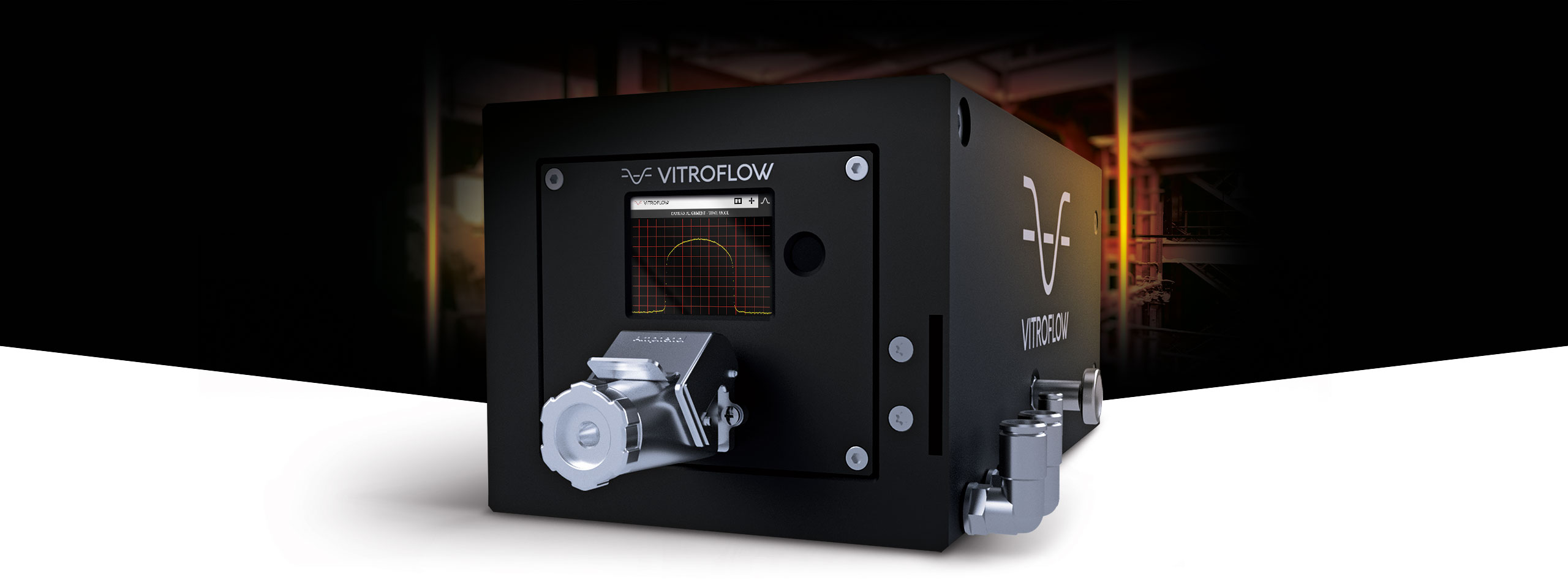

Monitoring glass flow with the VFM system significantly improves the way you control and overview your manufacturing process.

With a properly configured bushing controller, you will be able to control the glass flow with an accuracy better than +/– 0.4% by weight.

As a result, product density will be more consistent, generally lowering the weight of the finished product by 3–5%.

Features at a glance

Water Cooling

Water circulation throughout the entire sensor body ensures more efficient cooling and lower operation costs.

TFT Display

Integrated TFT display with Sapphire glass on the rear panel for quick status reading and alignment check.

Lens Protection

Integrated lens-hood designed to minimize water-spray and a Purger Air function to prevent dust build-up.

Pyrometer *

Stable stream temperature reading, measured at the same spot every time eliminating human errors.

Vibration

Detector *

Spinner abnormalities can be detected at an early stage.

Teflon™ Coating

Extremly durable design in Teflon™ coated aluminium ensures a long lifespan under demanding conditions.

Single Point Calibration

One sensor calibrates the entire line and thus eliminates the need for individual calibration of each sensor.

Industry Standard Protocols

Support for all standard Ethernet based communication protocols like Ethernet/IP, PROFINET, Modbus and more.

Remote System Access

The built in Web Server provides Remote System Overview, Diagnostics and Firmware Updates for smooth operation.

Built to scale

A modular system for easy and cost-effective expansion, supporting up to 40 sensors per system.

* Optional Feature

About us

Vitroflow is a company with more than 50 years of experience in glass flow measurement.

Operating from Höganäs in the southwestern part of Sweden, our team has designed, implemented and serviced hundreds of systems worldwide. Our knowledge and in-depth experience of the market enables full service and support for our customers 24/7.